Our Articles

The 2 Methods of MEP Coordination

With the increasing complexity and functionality of each system, MEP (mechanical, electrical, plumbing) activities are not confined to the traditional mechanical, electrical and plumbing systems, but also include fire protection, gas piping, process piping, pneumatic tubing, data systems, etc. If we assume that the design has been created by design consultants and then handed over to ‘installation sub-contractors’, they will validate the design and value engineer the design through the process of spatial coordination and procurement of components to meet the requirements of the design.

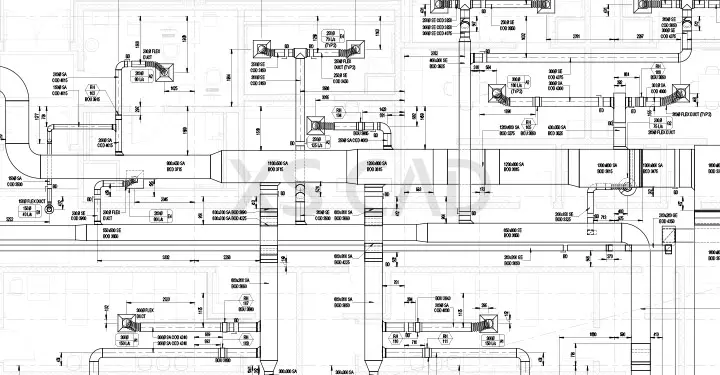

The coordination of MEP (M&E) systems amongst themselves and with other building systems, including architectural and structural disciplines, is a critical, challenging and time-consuming task, especially in complex building projects with intense MEP requirements. The coordination process of MEP systems involves defining the exact location of each building services system component throughout the building. These are located within the constraints of the envelope defined by the architectural and structural systems. These components and systems must comply with diverse design and operations criteria, avoiding any interferences/clashes amongst building systems. Most projects require MEP coordination, without which the site installation from a ‘design only’ set of drawings would be too much of a risk. There are two ways by which the MEP coordination process takes place: 2D MEP coordination, 3D MEP coordination.

2D MEP (M&E) Coordination

In an ideal world, 2D MEP coordination can work as long as all services (HVAC design services, electrical design services, plumbing design services) and systems are assessed adequately and added to a 2D drawing. The first process is as follows:

Challenges

3D MEP (M&E) Coordination

This process is more collaborative and allows the ability to communicate the progress of the project quickly and easily, providing 3D visuals that resemble the final system and service installation. The second process is follows:

Beyond the coordination stage, there are several other benefits from the 3D model and CAD drawing services, including use during facilities management, energy analysis and so on.

Irrespective of the MEP coordination method used, the need for MEP coordination arises due to the lack of detailed coordination during the design stage. Additionally, the need for fabrication and installation of building systems in accordance with industry and subcontractor best practice requires MEP coordination. The 2D MEP coordination process provides a limited interference-checking capability and therefore can and will result in more problems on site, including additional re-work, change orders and inflating budgets. All of this makes 3D MEP coordination a more efficient and the increasingly preferred method for the long term.

XS CAD has valuable experience providing BIM coordination services, CAD drawing services and HVAC drafting services and plumbing drafting services for global firms. Our range of services for building services design consultants and contractors across the world include MEP design and drafting for building systems, using AutoCAD MEP, Revit MEP, Navisworks and BIM 360 Design for collaboration.