Our Articles

Why MEP Component Manufacturers Should Adopt Revit Family Creation

Behind every building constructed for optimum human comfort is an efficient building services system. Ideally, this system, also known as an MEP (mechanical, electrical, plumbing) system or M&E (mechanical and electrical) system, would require reliable MEP components that will suit building requirements, function effectively and endure for the life of the building. Increasingly, manufacturers of these components are using Revit Family Creation services, specifically Revit MEP Family Creation services, to help design these components. Let’s look at how Revit Family Creation is a preferable option for MEP component manufacturers.

Building services systems are critical to human comfort in any building. Operating vital systems in a building, such as elevators, HVAC systems, electrical layouts and plumbing systems, it becomes crucial that the MEP components used are durable and precise. Manufacturers collaborate with engineers to ensure that performance requirements are satisfied and specific component properties, such as dynamics, conductivity and heat transfer meet the regulated standards and guidelines.

Modern methods of MEP component manufacturing have slowly made inroads into the more traditional methods. So, what do MEP components consist of and what are the different methods of manufacture?

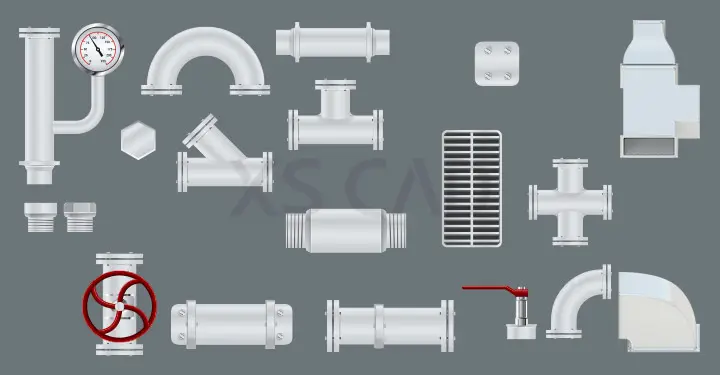

Pipes, ducts, valves, cables, connectors and any other component that facilitate the successful functioning of the mechanical, electrical and plumbing systems in a building are all MEP components. Manufacturing processes include injection moulding, machining, forming, joining, prefabrication and 3D printing, or additive manufacturing.

Manufacturers need to consider the process that suits them, depending on the volume of manufacturing, complexity, customisation and other requirements. In general, Injection moulding and forming methods are preferred for manufacturing of simple components in high volumes. The CNC machining process is useful for low volume manufacturing, where the surface finish and material properties are of paramount importance and the components are simple. It is recommended to use a professional 3D printer when there is a low volume of manufacturing involving highly complex components, customisation, fully assembled components or even when the parts are required quickly.

Using traditional manufacturing processes, moulds are created. Injection moulding and plastic forming finishes are smooth and there is a vast selection of material to choose from.

Prefabrication is a method of manufacturing that is steadily gaining popularity. In MEP systems, prefabrication is the process of manufacturing or assembling MEP components, such as flexible water pipes, pre-insulated heating/air conditioning ducts, plug and play cables, flexible sprinkler droppers, etc., in a factory or workshop that is removed from the construction site. The manufactured components are then transferred to the construction site.

Prefabrication of MEP components has several benefits, such as the following:

Additive manufacturing, or 3D printing, offers certain advantages in the manufacture of MEP components, such as enabling greater design freedom, mass customisation, reducing the need for assembly and can be cost effective for low volumes. The main 3D printing processes are selective laser sintering (SLS), binder jetting, stereolithography (SLA), poly-jet and fused deposition modelling/fused filament fabrication (FDM/FFF).

An additive layer process, 3D printing involves layers (.06 to .3mm thickness) being added over each other, which may cause a rough or ‘ribbed’ surface, especially when the component has curves, although high-quality printers can print thinner layers and thus produce a better surface finish compared to desktop-grade printers.

During 3D printing, components can be printed on demand and transported without tooling, resulting in relatively fast deliveries. Customised components can be expensive to manufacture using traditional methods, but 3D printing may be more affordable for parts or assemblies. Material choices are quite select in 3D printing, but this process will suit high-strength engineering plastics.

Once a decision is taken on the method of manufacturing, it is important to determine how design can be perfected before the process of manufacturing begins. Revit Family Creation can be an effective solution. A Revit Family is a group of elements with a graphical representation and common properties, or parameters. Revit Families are used to create building models and can include callouts, fixtures, tags and component details.

Both standard and customised elements can be added to a model, using predefined or created Families. Because these Families allow control over similar elements, design changes can be made easily and projects can be managed efficiently. There are different kinds of families: system families, which are already part of the software, loadable families, which are created externally and imported into a project and in-place families, which are families for customised elements within a single project.

Loadable Families can be part of categories such as pipe fittings, lighting fixtures, sprinklers, etc. Using Revit Family Creation, items such as plumbing fixtures, electrical fixtures, machine parts, elevators, insulators and HVAC pumps can be created.

The category of a Family specifies which parameters are activated.

Family Categories for MEP Components

- Air Terminals

- Cable Tray Fittings

- Communications Devices

- Conduit Fittings

- Data Devices

- Duct Accessories

- Duct Fittings

- Electrical Equipment

- Electrical Fixtures

- Fire Alarm Devices

- Generic Models

- Lighting Devices

- Lighting Fixtures

- Mechanical Equipment

- Nurse Call Devices

- Pipe Accessories

- Pipe Fittings

- Plumbing Fixtures

- Security Devices

- Sprinklers

- Telephone Devices

During the construction of large-scale projects, it can be difficult for design engineers to model products and fixtures several times. Using parametric Revit Families, engineers can control and optimise modelling time and facilitate coordination between manufacturers and contractors.

There is an increase in the use of BIM (Building Information Modelling) technology worldwide. Revit Families or BIM content can be created for as-built models. Models of MEP components can be created in a 3D BIM format and stored in an MEP content library, so that they can be replicated, modified and used again when required. Thus, using MEP Families, HVAC ducts, equipment, switches, lighting fixtures, toilet fixtures, pipes, cables, trays, etc. can be modelled. Manufacturers can then develop BIM content to work with MEP contractors for BIM workflows.

Advantages of Revit Family Creation

Using Revit Family Creation and through graphics, equipment parameters and the geometric details of actual equipment, such as boilers, can be displayed.

The Revit Family Creation Process

Some of the basic steps followed to create effective Revit Families are as follows:

Manufacturers are responsible for a gamut of tasks. Sometimes, it may not be possible for manufacturers to provide the relevant MEP services, due to constraints of finding technically qualified personnel, time and cost. In such cases, many Western firms outsource

MEP shop drawing services and the creation of an extended MEP content library to offshore companies with the required infrastructure and technically qualified and experienced professionals, who have had a history of providing high-quality Revit Family Creation services for a range of projects. Ultimately, manufacturers find that it is to their advantage, in terms of time, cost and quality output, to adopt the process of Revit Family Creation.