Our Articles

How the Hospitality Industry Benefits from Prefabrication

From functionality to attractiveness to technological modernity, the hospitality industry has witnessed steady progression in all areas. For some guests, the hotel bathroom is of paramount interest and importance. After a comfortable bed, hotel bathrooms are now recognised as one of the most marketable features of the hospitality experience, often crucial to keeping customers happy. Prefabricated bathroom pods and other prefabricated elements, such as walls and floors, can be created through prefabricated construction modelling to improve the experience. Prefabrication in construction, especially for specific elements in large numbers, such as bathroom pods for large hotels or hotel chains, helps create a safer work area and reduce labour, materials, waste, cost and time.

Luxury hotel bathrooms can provide mirror televisions, heated toilet seats, self-cleaning toilets, heated towel racks, directional water jets, water massage functions, dryers, deodorisers and entertainment sets. These features can be included in bathroom pods, or modules, as part of a system known as Design for Manufacture & Assembly (DfMA), using DfMA modelling and drawings.

Prefabricated modular construction involves building modules off-site in a climate-controlled factory. They are then transferred on-site and installed, significantly speeding up the entire construction process as well as ensuring consisting in the building. This leads to earlier occupancy and faster gains. Factors in construction, such as labour shortages, inclement weather and quality control, are easier to monitor and control.

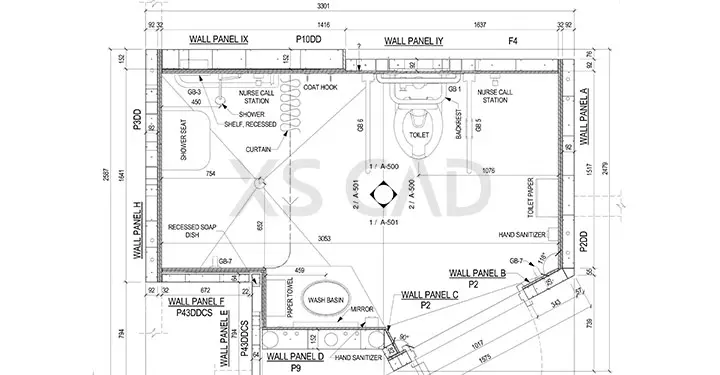

So what does a bathroom pod consist of and how is it designed? A custom-designed bathroom unit may consist of a toilet, wash basin, shower, bathtub and all other accessories and fittings required for a bathroom. Revit and AutoCAD in a BIM (Building Information Modelling) environment are software tools that allow modelling and detailing of modular construction pods so that manufacturing can progress seamlessly off site. The need to schedule different trade workers in the small space of bathrooms is eliminated, and worker congestion on site is minimised. The use of bathroom pods has been known to save almost 8 weeks of prime construction time and resulting costs.

The more complete process of prefabrication can be summarised as follows:

The primary benefits for using prefabricated bathroom pods are:

These benefits occur in prefabricated modular construction because of strict controls and tight inventory, and thus, prefabricated elements have fewer defects. It is becoming more popular to palletize mechanical equipment, or mount complex mechanical equipment permanently on a skid, increasing efficiency.

Furthermore, bathroom pod usage can improve purchasing, design, production and quality control, leading to shortened completion times. Here’s how:

Along with bathroom pods, prefabricated walls and flooring also benefit the hospitality sector. Panellised timber prefabrication units have significantly contributed to the industry. Prefabricated wood panel systems use complete timber floor cassettes and panellised walls. Other prefabricated wall panels, made of concrete, are fabricated in a factory, easing construction. Labour and material cost are reduced. A wall panel can be decorative, custom-made, enable insulation and sound-proofing, is easily replaceable, with easy finishing, resists weather effects, requires less maintenance and saves time and effort.

Specific advantages of prefabricated wall panels are:

Flooring Options

Prefabricated floors can be hollow core slabs, cassette floors and a combination of the two. Though cassette floors are light, ribs support their load-bearing strength and rigidity. Wood, concrete and ceramics are traditional materials to build floors and floor slabs. Timber floor joists were also popular but have been replaced by reinforced concrete. Casting concrete floors on site became difficult and expensive. Prefabricated flooring became a solution with its hollow core slabs and beam-and-block floor systems. Materials used include light concrete, reinforced concrete, pre-stressed concrete, ceramics, and their combinations.

The cassette system is relatively light and spans the same lengths as reinforced concrete. Both building erection and labour costs benefit; so do productivity, health, safety, build speed and build quality. Prefabricated floors are easy to construct, have requisite load-bearing capacity, have thermal insulation and less weight.

Who benefits from prefabrication?

Prefabricated modular construction with bathroom pods, wall panels and floors can benefit developers, inspectors, contractors and create consistent design throughout. Prefabricated construction modelling and modular construction drawings ensure accurate design details. The hospitality sector can thus complete projects faster, more safely, with reduced costs and high levels of quality control.